Edge coating

- Low paint volume 1,2L

- Suitable for small batch sizes

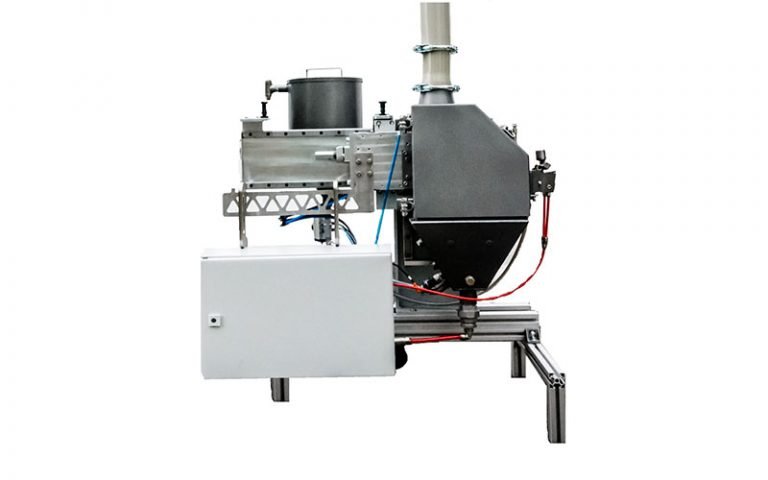

- Application head mounted on the base machine

- Working speeds up to 250m / min

- Fast material color change in 6 min

- viscosity control

Very compact design for direct mounting in the double end tenoner or suitable transports in direct connection to the profiling

Control cabinet and vacuum generator are positioned at a distance of 2-3m from the profiling machine

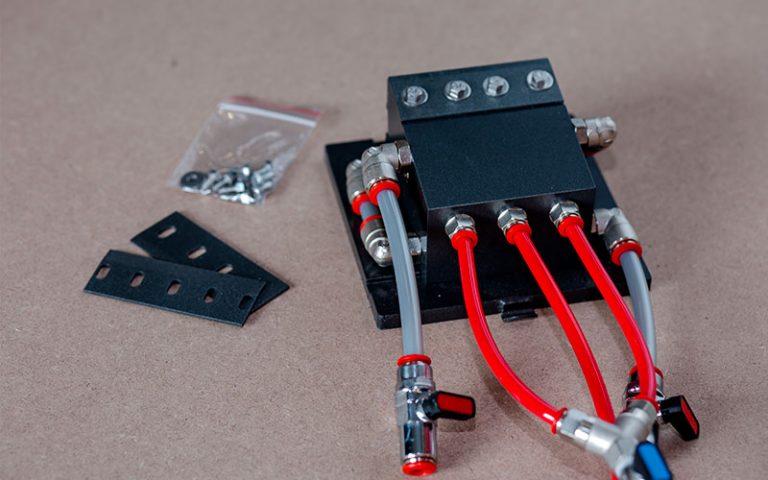

The entire paint management system is protected in a steel container

It is connected to the application unit via quick couplings

For maintenance purposes, this unit can be easily replaced

Edge coating head mounted directly on the basic machine

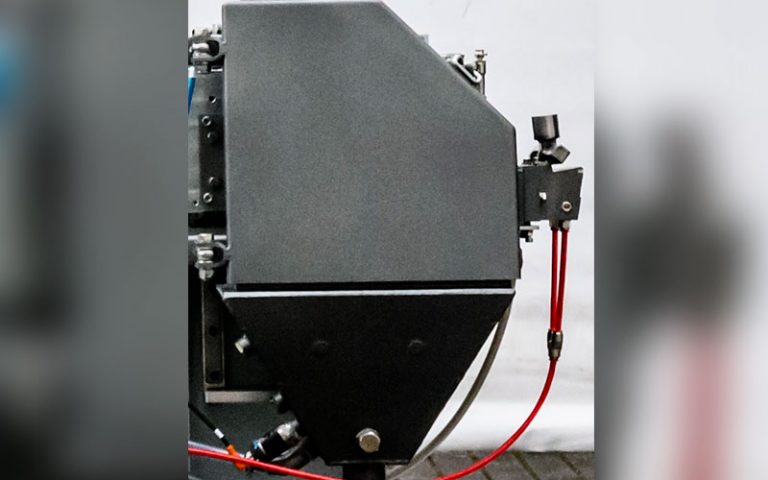

Edge coating head Vario Comfort with adjustable and easily exchangeable coating panels

The edge coating head is permanently dewed with moist air. Thus, no paint particles can adhere to the painting unit

Humidification is linked to the patented viscosity control

Sensor-controlled refilling of the used paint material

The paint tank is cooled to ensure quick cleaning (6 min).

A dew point control guarantees optimal condensation. This is associated with the viscosity control.